|

|

The goal

was to design a fixture which

could hold multiple 5/8" x

1" x 0.350" Bison Horn

Pieces for machining into tuner

button blanks on a table top CNC

milling machine.

|

|

|

|

|

|

|

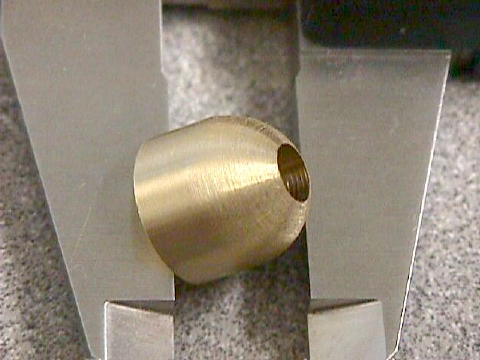

Here you

can see a completed tuner button

which has been shaped from

fossil ivory material |

|

|

|

|

|

|

|

|

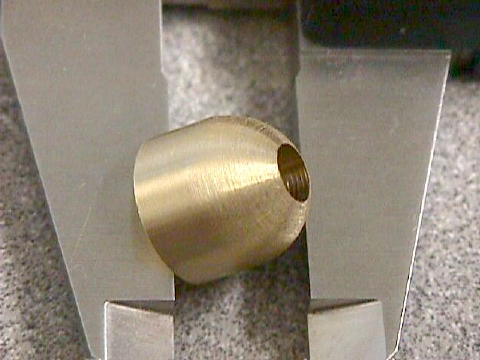

| I like to include a

caliper or other item in my

pictures to show the size of the

items being machined. |

|

|

|

|

|

|

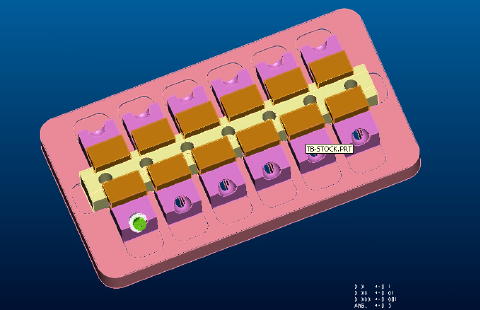

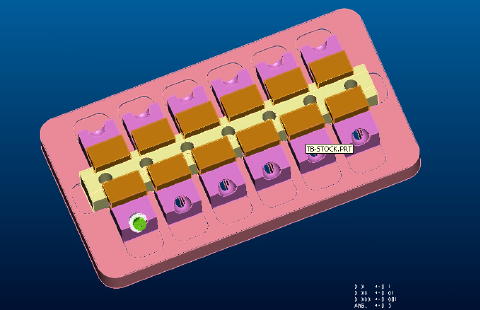

| Here is the solid model

of the fixture design I came up

with using the student version of

Pro Engineer. |

|

|

|

|

|

|

|

|

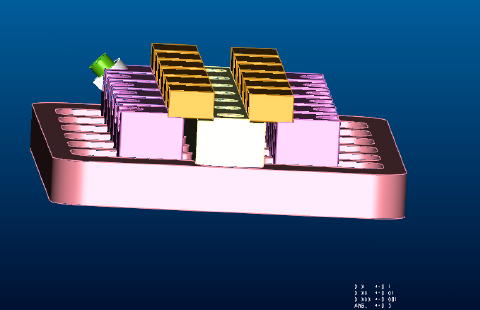

| This is a close up of

the vise like jaws which will hold

0.050" of the bottom of the

stock. |

|

|

|

|

|

|

|

|

|

|

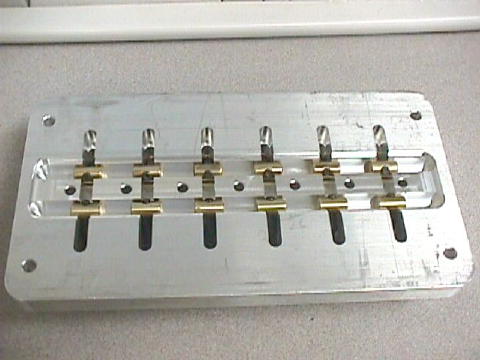

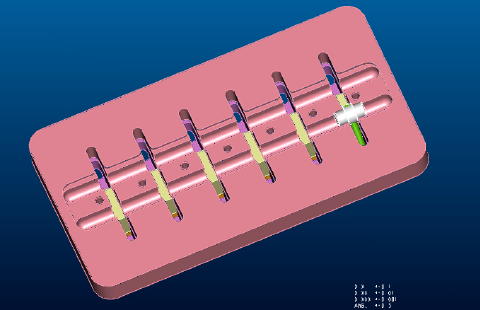

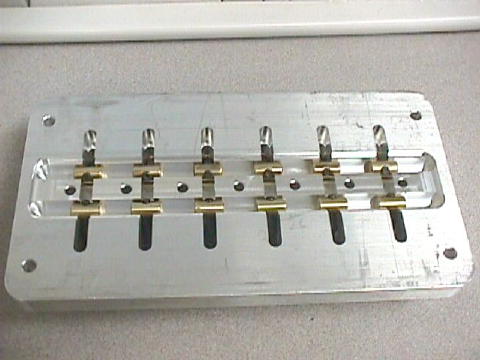

| Bottom view of the

fixture. |

|

|

|

|

|

|

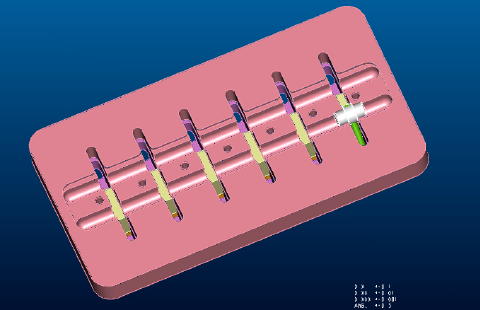

This is

the Convex space which supports

the 10-32 socket head cap screw

in the moveable jaw. |

|

|

|

|

|

|

|

|

| Another view of the

convex spacer |

|

|

|

|

|

|

Here you

can see the actual fixture which

has been machined and test fit

together. |

|

|

|

|

|

|

|

|

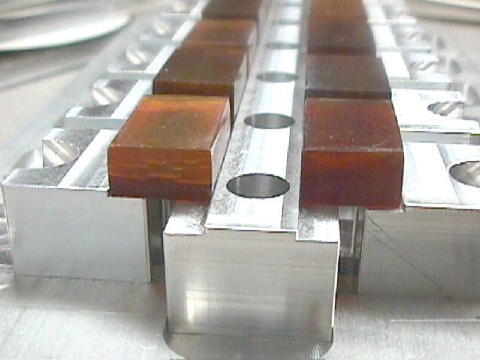

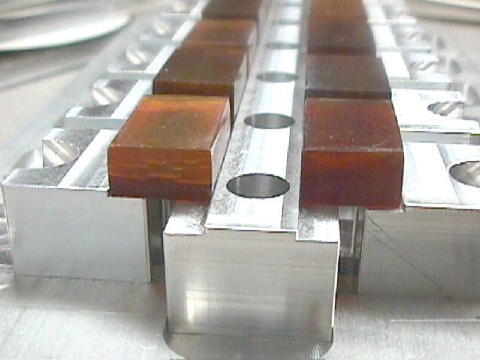

| Close up of the jaws on

the fixture. |

|

|

|

|

|

|

|

This is a

close up of the vise like jaws

holding 0.050" of the

bottom of the bison stock. |

|

|

|

|

|

|

|

|

| Here the fixture is

completely assembles and the stock

clamped into position for

machining. |

|

|

|

|

|

|

Another

view of the actual fixture and

stock ready for machining |

|

|

|

|

|

|

|

|

| Here is the bottom of

the fixture showing the nut parts. |

|

|

|

|

|

|

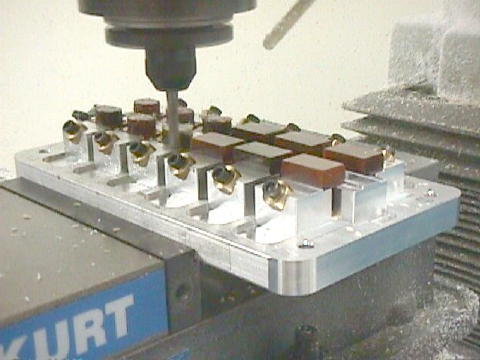

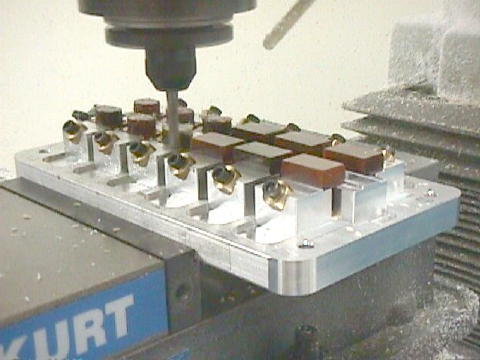

This is

the first set of parts being

test cut. I am cutting to a

depth of 0.280" in 3 passes

with a 0.010" finish cut. |

|

|

|

|

|

|

|

|

|

Another

view of the first set of parts

being test cut. |

|

|

|

|

|

|

|

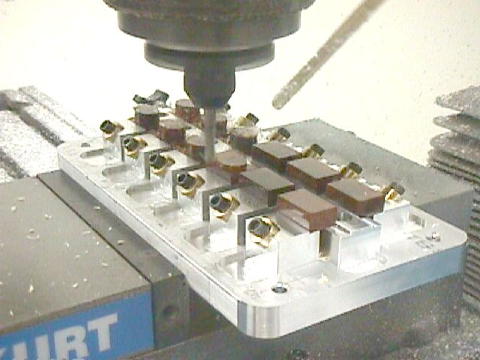

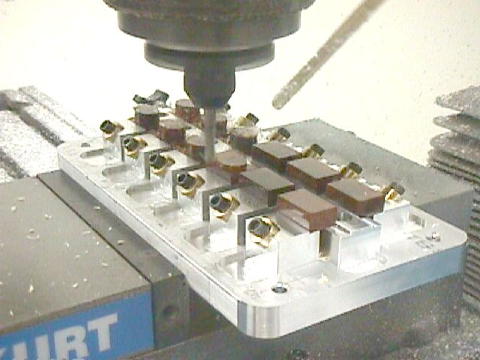

Another

view of the first set of parts

being test cut. This operation

took about 8 minutes to complete

and resulted in 12 good parts. |

|

|

|

|

|

|

|

|

|

In an

effort to try and speed the

process up, I tried a full depth

roughing cut with a 0.010 finish

cut. I feel that if the rough

stock had parallel sides I could

get a better grip on the parts and

this would cut the time in half (4

minutes).

|

|

I feel that

without changing the quality of the

stock that it will be possible to

significantly decrease the cycle

time by raising the spindle speed

and reducing the number of cuts to

depth. This should get us in the 5

minute time frame or less than 30

seconds per part.

|

|

|

|

|

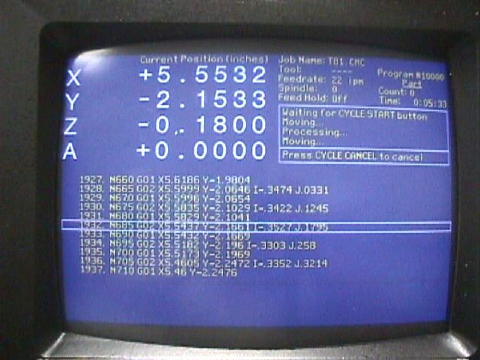

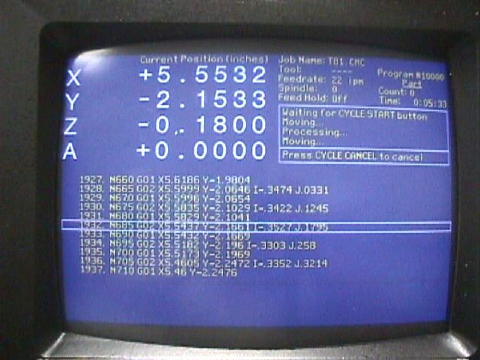

Screen

shot of the mill used for the

test cuts. |

|

|

|

|

|

|

|