|

| The job was to make

modifications to 4 separate parts.

There were 700+ pieces of

each part. |

I

determined that by assembling 3 of

the parts I could then simply

fixture one assembly and modify 3

parts in one setup.

|

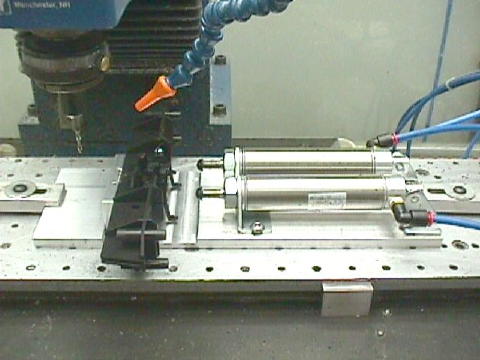

The block in the picture

provides both a reference point

and support to the assembly while

machining.

|

|

|

|

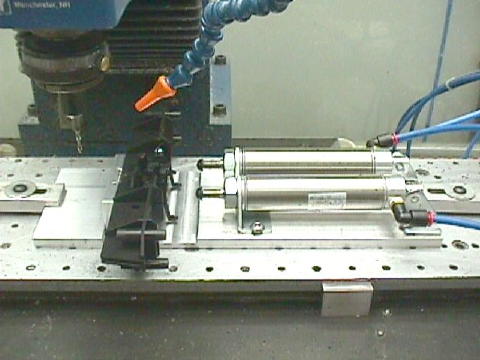

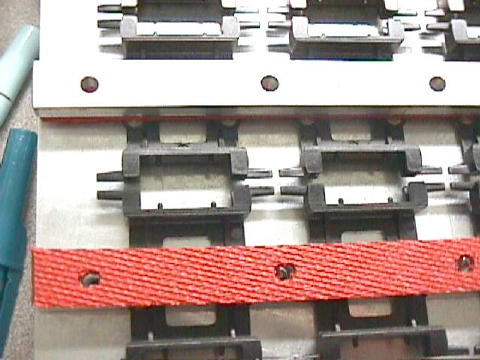

Here you can

see the assembled parts located

on the fixture ready to be

clamped. |

|

|

|

|

|

|

|

|

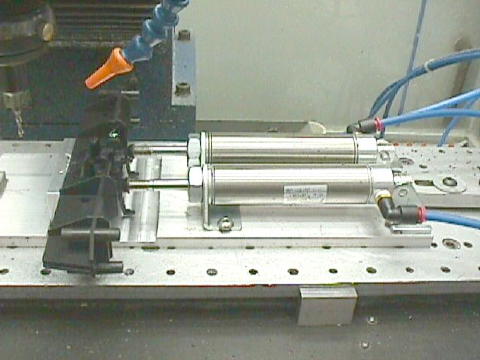

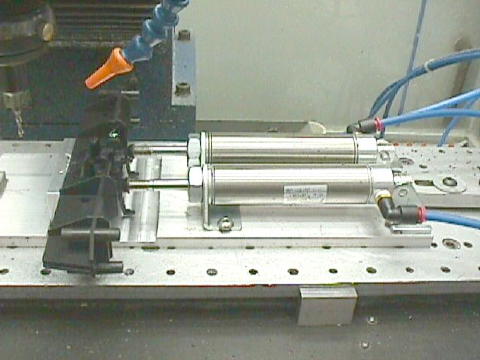

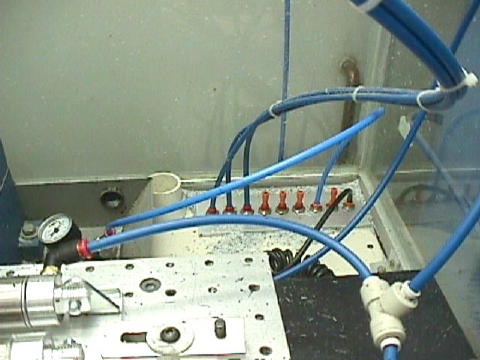

| Here is a view with the air

cylinders activated clamping the

part . |

I used air

cylinders with an integral return

spring to simplify the plumbing.

One air cylinder would have

provided sufficient clamping force

for the machining operation, but

it was more cost effective to use

2 air cylinders instead of having

to machine a cross member to clamp

the part.

|

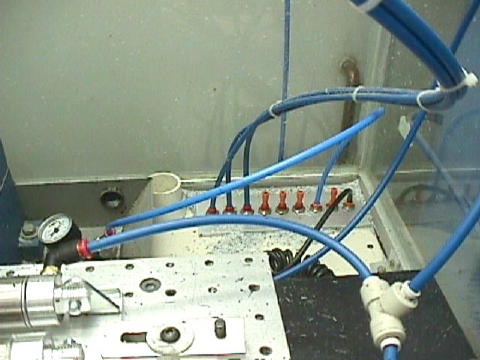

Instant tube fittings and

inexpensive 1/4" OD tubing

make quick connections to the

machines M-Function controlled

solenoid air valves.

|

|

|

|

| Here is a close up

showing the clamped parts after

modification. |

The machines

M-Function programmable air blast

was used to clear all the chips

while the table was being moved to

the parts change location.

After a short delay allowing the

part to be removed, another blast

of air clears any chips off the

top of the fixture. Another time

saving step resulting in faster

cycle times and reduced labor.

|

|

|

|

|

|

|

| A view of the bulkhead

fittings and table fixture plate

which allow quick fixture

changeover. |

|

|

|

|

|

|

The

fourth part was easy to fixture

using the stainless pins shown

in the picture to the right.

Because of the relatively low

number of parts I was able to

simply use an aluminum fixture

without fear of fixture wear

causing any problems. |

|

|

|

|

|

|

|

|

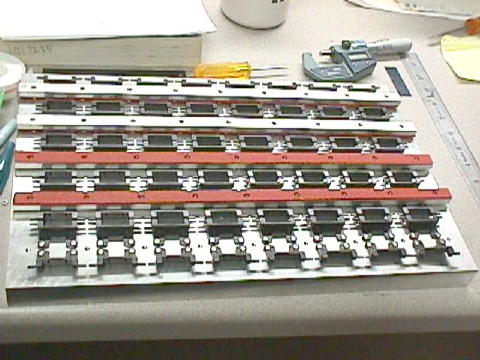

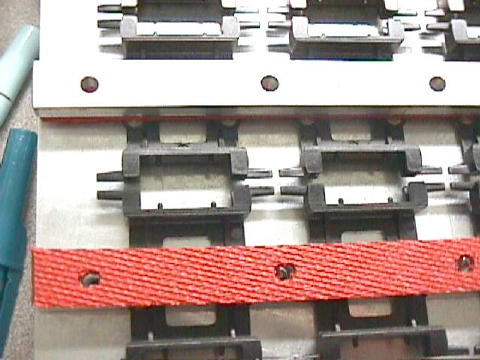

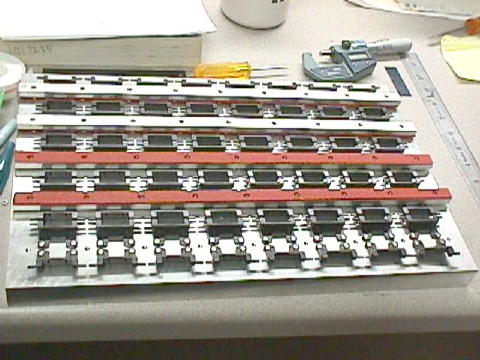

| Several pieces of

resilient rubber were used to

ensure that adequate pressure was

exerted onto each of the 80 parts

on the fixture. |

Socket head

cap screws were used in the tie

bars and they were tightened with

a torque sensing power tool to not

only speed parts change over but

to ensure equal force from each

screw.

|

|

|

|

|

A close

up of the parts on the fixture

and the tie bars. |

|

|

|

|

|

|

|