|

|

0.030"

Card Stock

|

|

The

goal was to produce a fixture

that could be used to fixture

some thin card stock and allow

the thickness to be changed

from 0.030" to

0.027", 0.026" and

0.025" Plus or minus a

few tenths.

|

|

|

|

|

|

|

|

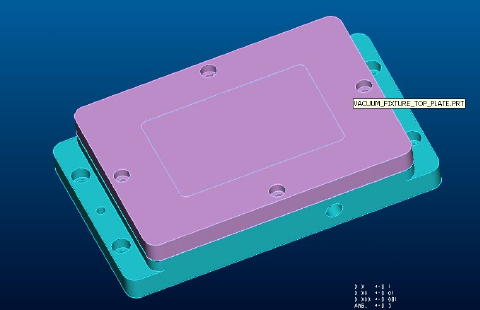

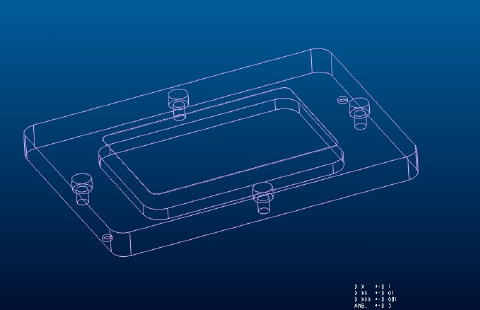

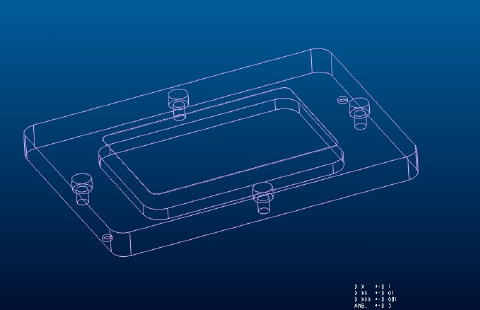

| Vacuum Fixture Assembly Bottom |

|

|

|

|

|

|

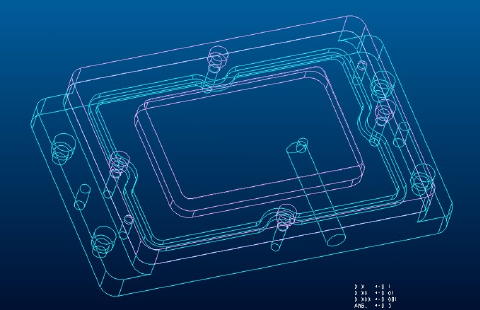

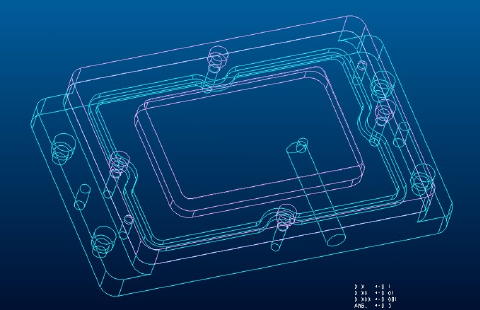

Vacuum Fixture

Assembly Wire Frame |

|

|

|

|

|

|

|

|

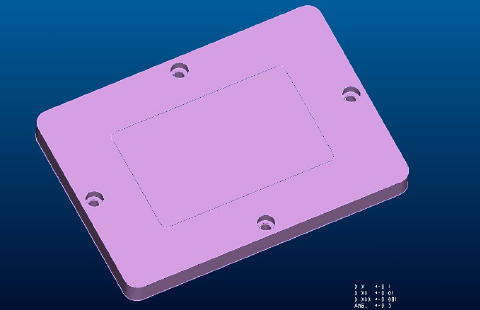

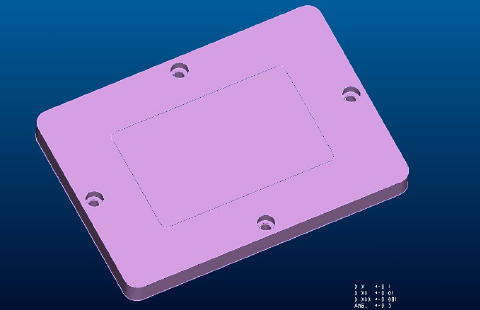

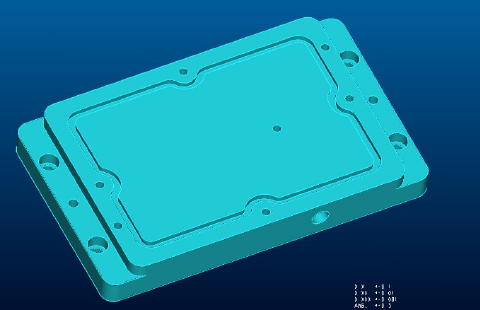

| Vacuum Fixture Top |

The

top pocket for the stock was

milled after the fixture was

machined and setup on the mill

where the job would be

run. The

top pocket for the stock was

milled after the fixture was

machined and setup on the mill

where the job would be

run. |

|

|

|

|

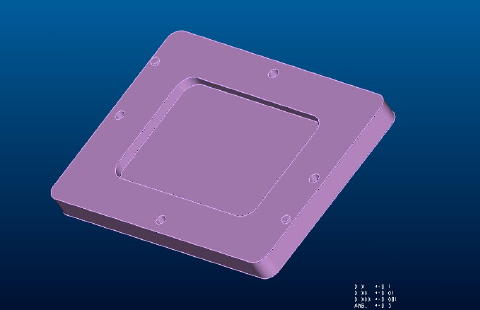

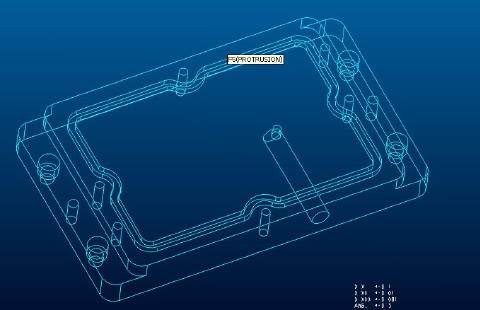

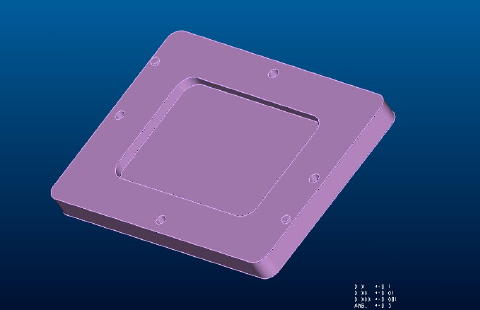

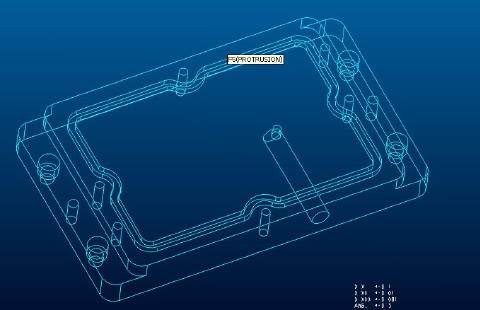

Vacuum Fixture

Top (Bottom View) |

In

this view you can see the offset

alignment pins which were

interpolated from the surface of

the part which mate with the base. In

this view you can see the offset

alignment pins which were

interpolated from the surface of

the part which mate with the base.

|

The hole

pattern was machined from

this side of the part. It

was just faster easier to

add the hole pattern in the

CAM program than in the

modeling system and that is

why you don't see the holes

in the model.

|

|

|

|

|

|

| Vacuum Fixture Top Wire

Frame |

|

|

|

|

|

|

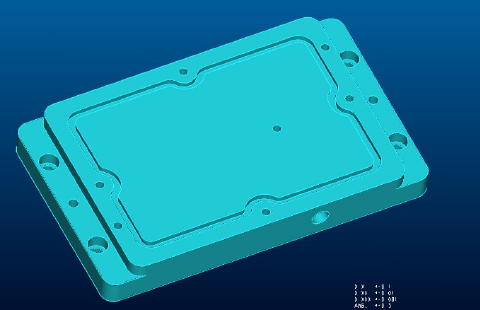

Vacuum Fixture Base |

In the base,

you can see the counter bored

holes for the screws that attach

it to the fixture plate on the

mill. The holes in between the

mounting holes are reamed to

assure repeatable alignment on the

mill.

|

The grove

around the base accepts a

round sponge rubber sealing

gasket material I found in

the Mc Master Carr catalog.

|

The

fixture is can be re-used by

simply machining a new top

plate. Notice the offset

alignment pin holes which

insure that the top plate

can be re attached in the

same location when switching

setups.

|

|

|

|

|

| Vacuum Fixture Base Wire

Frame |

|

|

|

|

|

|

|

|

|

|

|

|

|

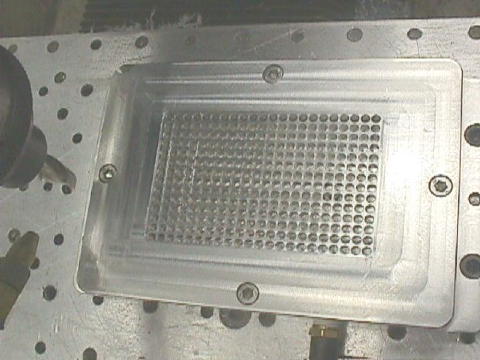

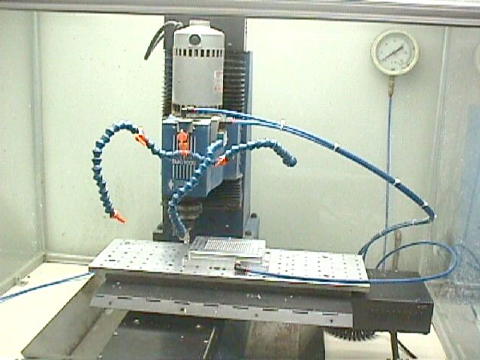

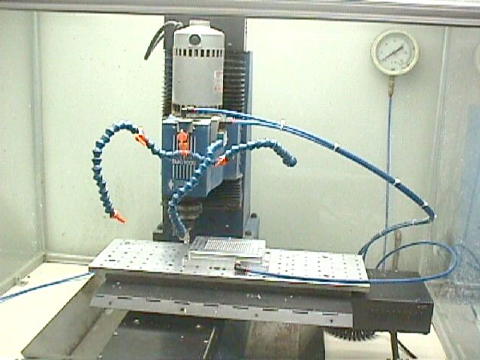

| Fixture On Machine 4 |

The

mill is already setup with a

pneumatic vacuum generator,

numerous solenoid valves which can

be controlled via M-Codes

and a vacuum switch which is

monitored via an M-Function to

ensure that the part being clamped

has reached a vacuum level which

will securely clamp the part. The

mill is already setup with a

pneumatic vacuum generator,

numerous solenoid valves which can

be controlled via M-Codes

and a vacuum switch which is

monitored via an M-Function to

ensure that the part being clamped

has reached a vacuum level which

will securely clamp the part. |

In the end we machined over

100 pcs of card stock and was able

to hold adequate tolerance for the

job.

|

|

|

|